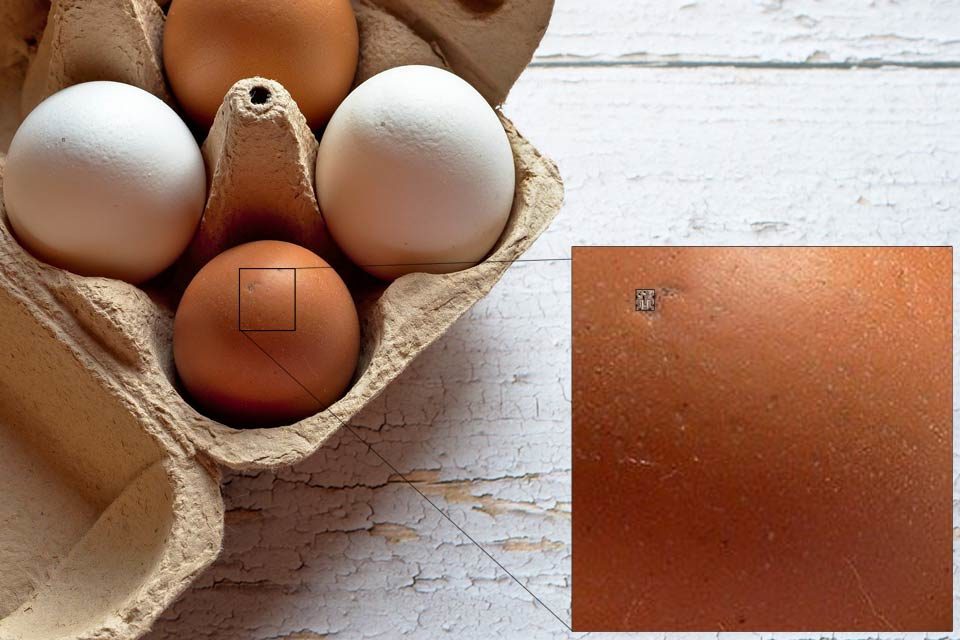

Secure supply chains: Researchers develop Pico SIM card for implementation in food

Researchers at the Massachusetts Institute of Technology have developed a new type of Pico SIM card to monitor supply chains. This could revolutionize supply chains in egg production, for example. The novel SIM card transmits data in a particularly energy-efficient manner via narrowband IoT (NB-IoT) and, in an initial proof-of-concept, transmits the geodata of individual chicken eggs from the barn to the breakfast table.

Regardless of whether cage-productin, free-range or even organically, the new Pico SIM card is attached to the outer shell of the eggs using a special adhesive process immediately after the washing process in the production line.

Due to their miniature design, the cards are completely biodegradable and also dissolve almost without leaving any residue during the cooking process. Manufacturers can thus meet their supply chain verification obligations far more cost-effectively with the new technology. The location data of the eggs are transmitted to a data platform in the cloud from the time they are laid, together with a time stamp and the production code. This is where the necessary certificates are generated. Via a mobile app, consumers can also track the laying date and place of origin of their eggs at any time.

The energy required for data transmission is provided by the “energy harvesting” principle. Here, the ambient temperature or the slightest movement of the eggs is sufficient to provide sufficient energy for communication.

The researchers are currently investigating how to get the SIM cards directly into the hens’ eggs. One idea is to add them to the animal feed. In this way, enough cards always reach the animals’ digestive tract and are also excreted with the eggs. If an egg is produced without a SIM card, this would be noticed during the collection process. These eggs could be sorted out accordingly and then still sold directly in the local farm store.

“With the new Pico SIM card, supply chains finally become transparent in a fully automated way,” a spokesperson of the MIT commented. In a first proof-of-concept, a large egg producer in the US is putting the new technology into operation just in time prior the easter season on April 1st.